Chainsaw for Trail Maintenance

In early 2020, I acquired a Stihl MS 362 C-M chainsaw for trail maintenance and got certified as a volunteer sawyer by the USFS.

In early 2021, after getting some good experience working in the field, I picked up a lighter Stihl MS 261 C-M chainsaw.

This isn’t so much a review of these saws (they’re great) as much as notes about my experience with them as a trail maintainer in the Ozarks.

MS 362 C-M

The MS 362 C-M was the first saw I used for trail maintenance. I chose this saw primarily because it was the lightest saw that supported the bar length I thought I needed, but the benefits and features of Stihl’s Professional line were also a factor.

I realize the Professional line comes at a premium price. I also realize that I have expensive taste and disposable income. However, I have found the Professional features, all combined, to be well worth the increased price. One in particular is very applicable to trail maintainers, who carry their saws for miles: the power-to-weight ratio. More on that later.

I didn’t know what bar length I needed before I got started. How big do trees commonly get in the Ozarks? The only clue I had were the instructions for the certification class, telling me what equipment to bring, which mentioned a chainsaw with a 18-24″ bar. I took that to mean that 24″ was the upper size I might need. The MS 362 was the smallest Stihl chainsaw that was rated for a bar that long. However, it turns out that a 25″ bar is excessive. For a trail sawyer in the Ozarks, I would recommend a 20″ bar. More on that later.

The MS 362 comes with or without the M-Tronic engine management technology. I have never been very good at adjusting fuel mixture on small engines, and I’m not technology averse, so it was an easy choice for me. Some have been vocal about problems they’ve had with it, but it has performed flawlessly for me.

Overall, I have been very happy with the saw. It runs great, and the only mechanical problems it has had were self-inflicted. It has plenty of power, and with the right chain, it cuts quite aggressively. My only regret is the weight. More on that later.

MS 261 C-M

Once I learned that a 25″ bar is unnecessary and impractical, I began wishing I had bought the MS 261 C-M instead. Why carry the extra weight for power I don’t need? I started thinking of this as my dream saw, as it seemed like the ideal size. My excuse came when the clutch broke on my bigger saw, and the parts were back-ordered.

According to the specs, the power head is 1.55 pounds lighter. However, fully loaded with a 20″ guide bar and chain, I have measured 2.4 pounds difference. I can definitely feel the difference when I pick one up. The weight difference is no minor thing. Carrying a lighter saw on your back, heaving a lighter pack on, and just operating the thing, especially when cutting upward or limbing elevated tree top branches, will all make a big difference after a long day of work.

Really, if you can’t cut something with a 20″ bar, then you probably shouldn’t be cutting it. Though I have a 25″ bar, I usually go out with my 20″ bar. There have only been a couple of times I wished I had my 25″ bar instead, but those would have just made big cuts a little easier, and I got the job done with the 20″ bar anyway. Theoretically, you can buck a log up to 40″ in diameter with a 20″ bar, but you can’t move a 40″ diameter log*.

(I actually recorded a 40″ diameter tree on one of the trails I maintain. I was eager to go tackle it until I did the math and figured out how hard it would be to move. A 12″ section of a 40″ diameter tree weighs about 600 pounds. And you have to assume the first section will be bound up.)

Beyond the weight, they both have all the same features and functionality, just smaller. The smaller saw came with an “E” guide bar instead of the “ES”. The Rollomatic E bar is lighter, made by laminating multiple layers, and is less expensive. The ES is machined from a solid bar, has a replaceable nose, and is stronger.

The MS 261 C-M comes set up for smaller .325″ pitch saw chain. I could have converted it (by changing the bar and sprocket) to use the 3/8″ pitch chain I already have, but I figure Stihl made the design choice for a reason, and the .325″ pitch chains are more readily available locally (and a little less expensive).

The Pack

If one can help it, one doesn’t carry a chainsaw long distances in one’s hands. However, few backpacks are designed to accommodate a chainsaw. I am presently using the Dakine Builder Pack 40L. It works okay, but there are many things I would change about it. I’m actually thinking about making my own.

In addition to my saw, I pack extra fuel and bar oil, chaps, gloves, safety glasses, extra chains and sometimes an extra bar, my scrench, wedges, and a first aid kit. Plus normal trail stuff: water, lunch, snacks, trowel and TP, a paper map, bandana, swiss army knife, matches, compass, and headlamp.

If I start out with the saw’s tanks full, a 32 oz. can (a quart) of fuel is usually just enough to get me through a full day. The round containers of premixed fuel fit in one of the pockets well (the square cans sold by Stihl don’t fit). I have a 16 oz. polyethylene bottle for bar oil that fits nicely in another pocket.

I have been carrying my helmet and my axe separately. I’d like to work out a way to rig them onto the pack. The Builder Pack has a way to attach long tools, but the handle of my axe, which is a Collins Boys Axe, is too short to be held that way. I really love the boys axe for this purpose. I’m thinking about modifying the Builder Pack with a kydex sheath to hold it.

The helmet I normally use is the Stihl Advance X-Vent system. I really like it, except for one thing: the face shield wants to fall off when I’m carrying it. I’ve already lost one (and the replacement is three separate parts). I have to keep an eye on it when I’m carrying it, and I’m worried that if I hang it on my pack somehow, I’ll lose it.

The reason for carrying an extra bar is to deal with my bar getting pinched. If I can’t get my bar out of the tree I’m cutting, I can remove it from the powerhead and put on the other bar and another chain. With that, I can rescue the stuck bar and chain. However, if I’m out with another sawyer who has their own saw, then I don’t really need to bring an extra bar.

My Body

(Don’t worry, there won’t be pictures.)

Fully loaded, with the saw and everything, my pack weighs about 40 pounds. I usually manage less than that when I go backpacking. I’m not a big guy, and I sit behind a desk all day, so this proved to be a big challenge.

The first few times I went out, it about killed me. Huffing and puffing up hills (on a trail with no switchbacks) forced me to take numerous breaks to catch my breath, and it took a lot out of me. Making upward cuts, struggling to put the pack on each time I moved on, it added up fast. I was exhausted after a few hours.

When a chainsaw is involved, exhaustion is a safety concern.

I finally had to do something about it. I dusted off my bicycle, found a paved trail with some hills, and started riding two or three times a week. Several weeks of this made a significant difference. Still, this was no small commitment. (The trail was more than an hour’s drive away, so I was investing 3+ hours each time I went.) In one sense, I was building up my endurance so I could do trail maintenance. In another sense, the trail maintenance was a wake-up call to how physically unfit I had become.

The biking got me most of the way. It strengthened my legs some, and it greatly improved my aerobic capacity. After that, sawyer outings became the exercise, and each time I went out got easier. My work days grew longer and my exhaustion became less. Now I can go out, put in an eight or nine hour work day, sometimes hiking several miles, and I’m just a little sore afterward. My legs are rock hard now.

The experience has been great training for backpacking. I went on a weekend trip several weeks ago (scouting a new trail section for maintenance needs), and the hiking part was no big deal. I didn’t think much about it at the time, but previous backpacking trips have involved a fair amount of exhaustion and heavy breathing, and now they don’t.

So, if you’re not in shape for backpacking, then you’re probably not in shape for carrying a saw pack.

Saw Chains

It is just a fact of life for trail sawyers that many of the trees to cut have been on the ground long enough to be embedded in the dirt, if not decayed and fused with it. Dirt, sand, and rocks are hell on saw chains. Get your chain in the dirt, and it will dull almost instantly. When you see discussions of “dirty” or “abrasive” conditions, they are talking about situations like this.

When I bought my saw, it came with Stihl’s Rapid Micro 3 (RM3) chain. This has a semi-chisel tooth shape, which is purported to retain its sharpness longer than a full-chisel tooth, especially in dirty conditions. I suspect this is because it is ground with a steeper (75°) cutting edge. It also has a single-hump drive link, which reduces kick-back. I stuck with this type of chain for quite a while. It is the least aggressive, but it still cuts plenty quickly, and I have found it to be the most controllable. If you are a new or uncertain chainsaw user, I definitely recommend this chain. Unfortunately, no one stocks it locally for 25″ bars.

I am now using primarily RM chain. This is the same as RM3 with the semi-chisel tooth, but the drive links have no humps for low kick-back. This chain cuts much more aggressively than RM3, and it is available locally for my longer bar.

I have also tried RS chain, which has a full-chisel tooth. This is supposedly the most aggressive chain Stihl sells, although to me it seems about the same as RM. It might be my imagination, but it seems to cut a little straighter. RS chain is ground with a 60° cutting edge, and it supposedly loses its edge faster, especially when dirt is involved. If I was felling trees or cutting firewood, this is the chain I would use.

I’m thinking about trying Oregon DuraCut DPX, which is made of a tougher chrome-moly alloy and some better kind of plating.

I have had bad days with chains. Keeping my chain out of the dirt while bucking trees on the ground is a skill I am still learning. I have gone through enough chains in a single day that I am now carrying four extra. That said, it has been a long time since I’ve needed that many, so maybe I’m getting better.

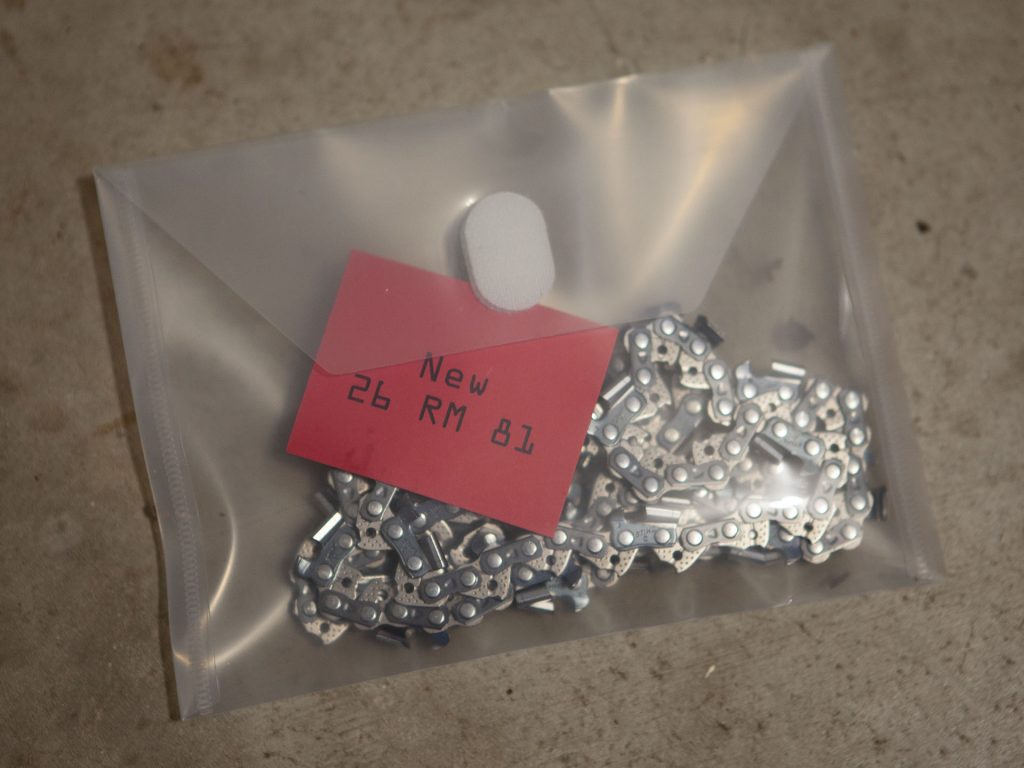

Chains are sharp and oily, and once they’ve been used, they’re dirty, so I don’t just throw them into my pack. I haven’t found the perfect solution. The cardboard boxes the chains come in are a little oversized, and they get crushed. I’ve tried polyethylene plastic boxes, but I never found any that were an ideal size or strength. I was having okay luck with zip-lock freezer bags, but then they stopped making them in the pint size. I have started using tougher plastic envelopes with velcro closures. They are working well, but I wish I could find them in a little smaller size.

So I can keep track of which chains have been used up, I have been putting colored slips of paper in the containers to indicate which chains are sharp, and when I put a dull chain back into the container, I discard the paper. I use one color for new chains and another color for sharpened chains.

Forget about sharpening your chains with a hand file. If you get your chain a little dull by cutting a lot of clean wood, then it’s probably practical. However, dirt and rocks tend to chip and round off a significant amount of the tooth. I frequently have to take off 3/32″ of material to get them sharp again. It would take you forever to fix that with a file. They need to be sharpened with a grinder. I had been sending mine out, which tends to be more of a hassle than it seems, and there is also a cost. I have lately bought a saw chain grinder, and I’m just now getting the hang of it.

“26 RM 81″ in the photo above is how Stihl refers to the chain I use on my MS 261 C-M. The 2 indicates .325″ pitch, the 6 indicates .063″ gauge. RM is the Rapid Micro semi-chisel tooth type, without the low-kickback drive link hump. 81 is the number of links needed for the 20″ bar. For the 25” bar on my MS 362 C-M, the chain I want is 36 RM 84. (The relationship between 26 and 36 in the chain size code and the model numbers of the saws is purely coincidental, but it’s working out to be an easy way to remember.)

Fuel

If you buy fuel at the gas station, it has some amount of ethanol in it. Ethanol is hard on small engines and will eventually cause premature failure. If you spend several hundred dollars on a chainsaw, you don’t want that to happen. The easiest way to get ethanol-free fuel is to buy the premixed fuel.

I have mostly been using TruFuel. It is less expensive than the Stihl MotoMix, and evidently TruFuel manufactures the Stihl fuel for them to their specifications. (I just found out that the larger TruFuel containers are not a gallon, they are only 110 ounces!) The least expensive I have found is a Sunoco brand, which you can sometimes find at Menards or Rural King. I just watched a video comparing four different brands of fuel, and it has me thinking about going back to Stihl MotoMix.

The round quart cans work well in my pack, though they do tend to get dented up over time. The opening is a good size to fill the saw directly without a funnel. I keep them and refill them from larger containers. Finding the right size funnel to refill them was a little challenging. I have heard some people talk about using liquid camp fuel bottles, which might be less prone to being dented.

As I said, starting out with a full tank in the saw and a quart of fuel in my pack is usually enough to get me through a full day. However, a long day with a lot of sawing can exceed that. If you know there are a lot of trees down in a short space, especially if they are big ones, and you’re the only one bringing a saw, it would be a good idea to have your swamper carry another can of fuel for you.

Malfunctions

My MS 362 C-M has failed and had to be repaired twice. The first was definitely self-inflicted, and I believe the second failure was as well.

The first failure happened when I nicked my saw chaps. I didn’t even notice it until someone pointed it out to me. Anyway, a bunch of the fibers got pulled out and wrapped themselves around the sprocket. That’s what they are designed to do, but there wasn’t enough of them to stop the chain. Instead, they worked their way into the needle bearing in the clutch. The chain wouldn’t stop when idling, the engine wouldn’t idle right, and it would stall sometimes when revving up. I ultimately had to replace the needle bearing, since fibers had fused to the plastic cage. I was able to pick up this part locally.

The second failure may have been caused by a poor repair on the first. Symptoms similar to the previous incident, but worse. I discovered that one of the clutch shoes was broken, cracked in half. Also, all of the needle bearings were missing from the cage. I’m guessing that the needle bearings came out and became foreign objects inside the clutch, causing the cracked clutch shoe. I also suspect that the needle bearings had failed because I decided they shouldn’t be lubricated. (In fact, they should by lubricated.) I decided I should replace the whole clutch, which didn’t cost much, but it was back-ordered and took a while to get.

Battery Saws

One of the sawyers I work with got himself an EGO CS1804 saw, and it has been an interesting experiment.

We learned right away that cutting big logs with it kills the battery quite rapidly. However, if he sticks to smaller stuff, he can get quite a bit done with it. We generally go out together, and he’ll take the smaller things: bucking logs maybe 8″ or 10″ in diameter, and limbing tree tops. For bigger things, we’ll use my saw. Working this way, we can generally get through a full day and he’ll still have one or two bars left.

Theoretically, he could buy a second battery, but it would be a significant investment.

I can’t say I would recommend that particular saw. The design and build quality isn’t that great, and clearly EGO doesn’t have much experience making chainsaws. It has a single mechanism for attaching the bar and adjusting the chain tension, which doesn’t work very well. He has also had problems with the oiler, causing it to fail sometimes.

Stihl makes battery saws, and Milwaukee makes one that is highly praised. I haven’t witnessed either of these in action.